Mechanical and Electrical & Instrumentation

Limetree Bay Terminal Restoration And Restart

This island project shows the importance of developing relationships with local vendors and using effective communication avenues as a part of superior customer service for a client.

Location

Contract Value

Duration

Project Scope

Markets

Project Status

Project Description

The Hovensa Facility closed, decommissioned in 2012, and remained dormant until December 2015. In the initial restart phase, the terminal will bring 13 million barrels of storage online, the first of which is promised to various customers. The LB Terminals facility consists of approximately 32 million barrels of crude oil and petroleum product storage, a deep-water port with 10 petroleum docks, one bulk product dock, and six tug boats to support the terminal operations. In the second phase, another 13 million barrels of storage capacity will be brought online, contingent upon demand from potential customers. The facility currently blends and stores crude, gasoline, diesel, propane, jet fuel, and fuel oil.

EXCEL repaired and turned over 21 storage tanks totaling over 8.7 million barrels of storage capacity back to operations. Each tank presented different challenges related to its required and recommended repairs. Due to the facility being closed and decommissioned three years prior, the dormant storage tanks were exposed to the Caribbean environment, causing damage.

Quantity Installation Summary

| 98,850 ft | Mechanical Piping |

| 30,000 ft | Cable Tray |

| 200,000 ft | Conduit |

| 160,000 ft | Tubing |

| 2,200,000 ft | Cable |

| 112,384 | Terminations |

| 2,700 | New Instruments Installed |

| 4,500 | Lights/Panels/Transformers |

| 11,000 | I/O Point-to-Point & Functional Checks |

| 1,684 | Control Valves |

| 118 | MOVs |

| 1,226 | Motors |

| 14 | Compressors |

Other Mechanical Projects

Chemical / Petrochemical

Facility Capacity Enhancement

EXCEL Group proudly announces a client partnership to increase a Louisiana facility's capacity and output.

Mechanical, Electrical & Instrumentation, Fabrication

View Project

Food & Beverage

CP Kelco Eagle Phase 2

The CP Kelco Facility enhancements represent a significant expansion project known as Eagle Phase 2.

Mechanical, Electrical & Instrumentation

View Project

Chemical / Petrochemical

Formosa HAPF Expansion

This project created a brand new HAPF Unit inside Formosa Plastics in Baton Rouge, LA.

Mechanical

View Project

Chemical / Petrochemical

Dow LA2 Lifetime Extension, WERs 1 & 2

Mechanical, Electrical & Instrumentation, Turnarounds, Fabrication

View Project

Chemical / Petrochemical

BASF QL4 Cooling Tower Replacement

A cooling tower replacement as part of a larger scope of work.

Mechanical, Electrical & Instrumentation

View Project

Oil and Gas

EXXON NCLA Turnaround

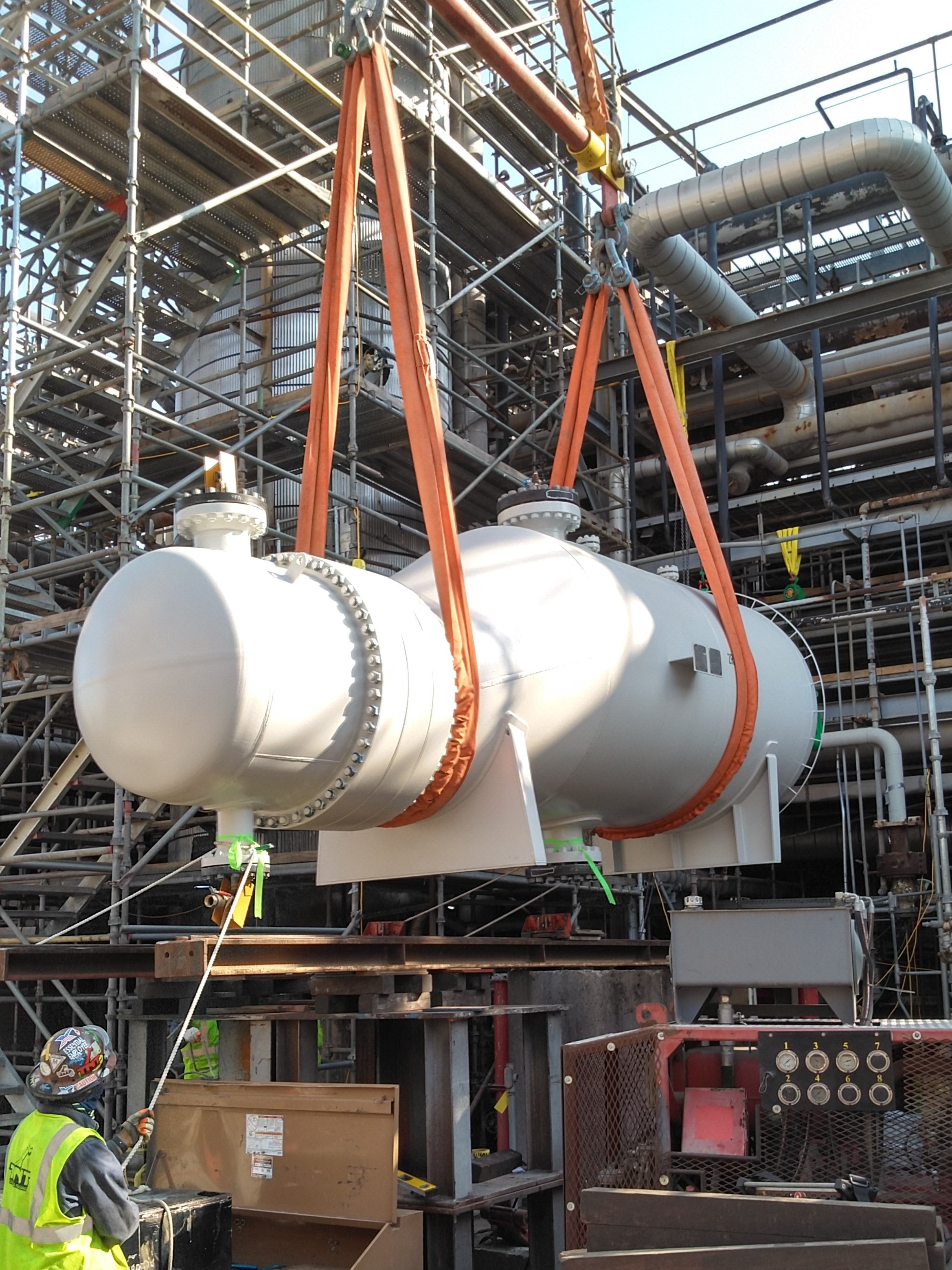

Equipment replacements and new installations as part of the Garden City Turnaround.

Mechanical, Turnarounds, Fabrication

View Project

Oil and Gas

BASF Amines Turnaround

Excel Provided Fabrication and Mechanical Services.

Mechanical, Turnarounds, Fabrication

View Project

Agriculture / Fertilizer

CF Industries Turnaround

EXCEL Provided Mechanical and Electrical & Instrumentation Services

Mechanical, Electrical & Instrumentation

View Project

Oil and Gas

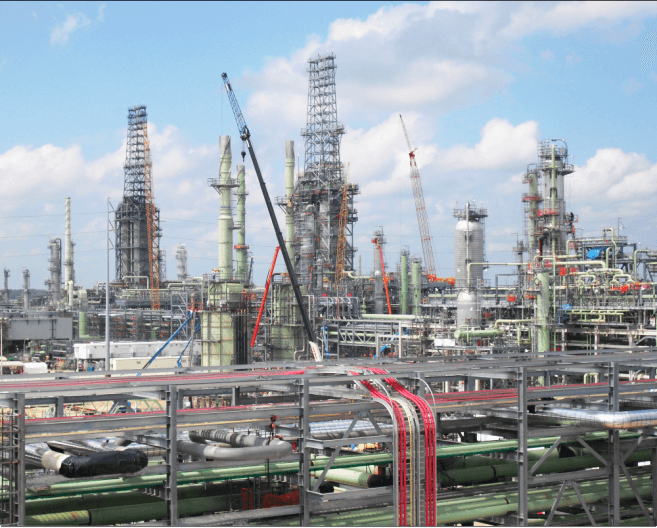

Marathon Garyville Major Expansion Project

This mega project was the largest in Gulf Coast history.

Mechanical, Electrical & Instrumentation

View Project

Terminals, Midstream

New Dock 14 Demolition & Tie-Ins Expansion

Mechanical, Fabrication

View Project